In the realm of material science and engineering, understanding the mechanical properties of materials is paramount. Tensile testing, a fundamental procedure in this field, involves subjecting a material sample to a controlled tension until it fractures. This process provides critical information about the material's strength, ductility, and ultimate failure point. This is where customized tensile testing machines come into play, offering tailored solutions to meet the unique needs of various industries and applications.

The Importance of Customized Tensile Testing Machines

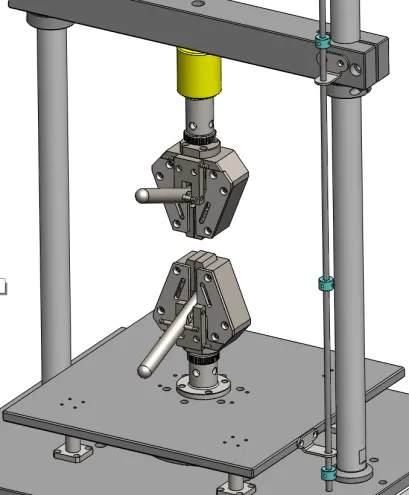

Standard tensile testing machines are designed to cater to a broad range of materials and testing scenarios. However, specialized materials or specific industry standards often necessitate a more precise approach. Customized tensile testing machines allow for adjustments in load capacity, speed, grip type, and other parameters to suit the exact specifications of the material being tested. This level of customization ensures that the test results are accurate and relevant to the material's intended use.

Key Considerations for Customization

When considering a customized tensile testing machine, several factors must be taken into account:

- Material Type: The type of material being tested (e.g., metal, plastic, textile) influences the choice of grips, fixtures, and load cell capacity.

- Test Standards: Compliance with international or industry-specific standards may dictate the testing protocol and machine specifications.

- Load Capacity: The maximum load the material is expected to withstand determines the machine's force capacity.

- Testing Speed: The rate at which the material is pulled affects the test outcome, necessitating precise control over the testing speed.

- Data Acquisition: Advanced software and sensors are crucial for capturing and analyzing the test data accurately.

ITM-LAB's machines are designed to meet stringent quality standards and are capable of handling a wide array of materials and testing scenarios. Our commitment to innovation and customer-centric approach has made them a trusted partner for clients seeking tailored testing solutions.

Conclusion

Customized tensile testing machines are indispensable tools for researchers, engineers, and quality control specialists who require precise and reliable data on the mechanical behavior of materials. By tailoring the testing equipment to match the specific characteristics of the material and the testing requirements, these machines provide invaluable insights that inform product development, manufacturing processes, and safety standards. With companies like ITM-LAB at the forefront of innovation, the future of material testing looks promising, offering tailored solutions that empower industries to build stronger, safer, and more efficient products.