The Role of Fatigue/Durability Testing for Electronic Devices

Key Benefits:

- Ensure Stable Operation: Validate long-term functionality to avoid unexpected failures.

- Identify Design Weaknesses: Detect issues in design or material that could lead to malfunctions.

- Verify Safety: Ensure the device complies with safety standards and protects users.

- Improve User Experience: Reduce product failure rates, leading to higher satisfaction.

- Optimize Manufacturing: Refine processes and materials for better durability.

- Boost Market Competitiveness: Offer reliable products that stand out in the market.

- Achieve Compliance: Meet industry regulations and certifications.

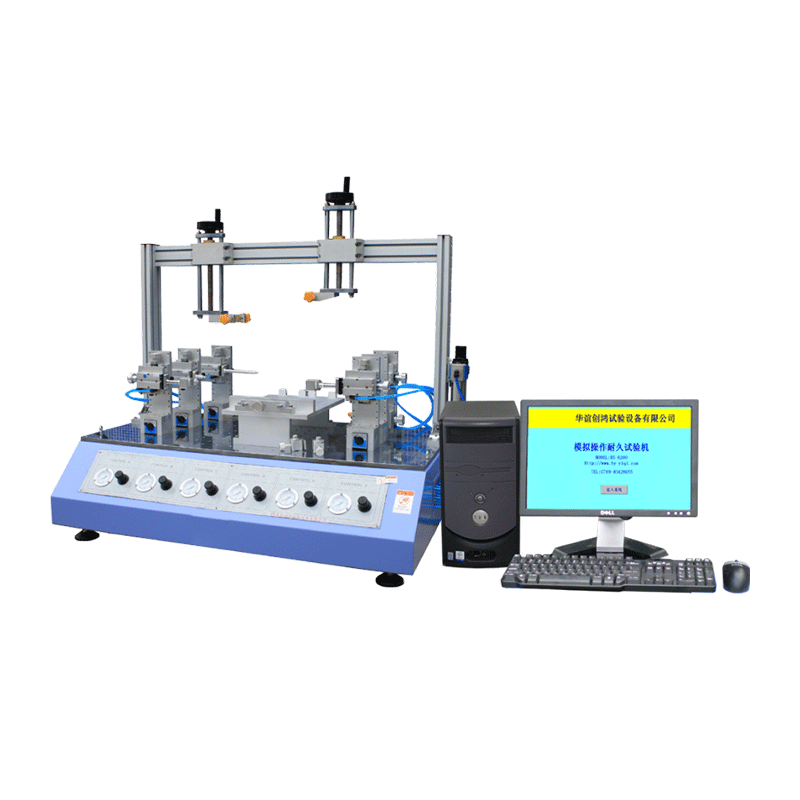

Current Equipment for Fatigue/Durability Testing

While there are numerous machines for fatigue and durability testing, most are designed for single, targeted tests. For example:

- Button testers for mechanical buttons.

- Insertion/extraction testers for connectors and ports.

- Vibration test machines for structural integrity.

Advantages of Single-Test Devices:

- Simpler design.

- Lower cost.

- Highly specialized and accurate for specific tests.

Disadvantages:

- Cannot handle multiple test types simultaneously.

- Requires multiple devices for comprehensive testing.